Introducing our state-of-the-art 1000BPH Semi-automatic Bottle Blowing Machine, designed to revolutionize your bottle manufacturing process. With a production capacity of 1000 bottles per hour, this machine combines efficiency and precision to meet the demands of your growing business. Crafted from high-quality materials, it ensures durability and longevity, minimizing maintenance costs. Equipped with advanced technology, it offers seamless operation, producing uniform and flawless bottles every time. Its user-friendly interface allows for easy control and adjustments, making it suitable for both experienced operators and beginners. Invest in our 1000BPH Semi-automatic Bottle Blowing Machine and experience unparalleled productivity and quality in bottle production.

Description

WBS-2 Semi-automatic Bottle Blowing Machine is suitable for producing plastic containers and bottles from 10-2000ml. It is widely to produce Soda bottle, mineral water, carbonated drink bottle, pesticide bottle, oil bottle, wide-mouth bottle etc.

- Adopt Specil electronic controlling circuit heating; high efficiency in simultaneous controlling one lamp or more; low power consumption.

- Adopt the theory of heat transfer and feedback while designing the shape and thickness of preform.

- the preform will be heated evenly by this semi-automatic bottle blowing machine, not be influenced by outside environment.

- cooling system with cold air cycle ensures same heat exposure of internal and external surfaces of the bottles.

- the air exhaust system designed by CAD can guarantee the deviation of heating furance temperature+/-1 degree.

- Air circuit system consists of movement and blowing so as to meet the needs of different air pressure, also to provide stable high pressure for blowing different shapes of big capacity bottles.

- the system is equipped with silencer, connecting rod and articulated refueling devices.

- Two modes of operation:semi-automatic mode and automatic mode.

- Small size, low investment, one person enough to operate, simple and safe.

Technical Parameter

| ITEM | UNIT | WBS-2 |

| PRODUCT | Theoretical output | Pcs/hr | 1000 |

| Max.Volume | L | 3 |

| Max.Height | MM | 360 |

| Max.Diameter | MM | 105 |

| MOLDING | Number of cavities | / | 2 |

| Mould Plate Dimension(L*H) | MM | 490*405 |

| Mould Thickness | MM | 220 |

| Mould Opening stroke | MM | 160 |

| ELECTRICAL | Power |

| 220-380V/50-60HZ |

| Total Power | KW | 11 |

| Heating Power | KW | 10 |

| MACHINE | Main Body Dimension(L*W*H) | M | 1.5*0.65*2.0 |

| Main Body Weight | KG | 550 |

| Pre-heater(L*W*H) | M | 1.4*0.60*1.40 |

| Pre-heater Weight | KG | 300 |

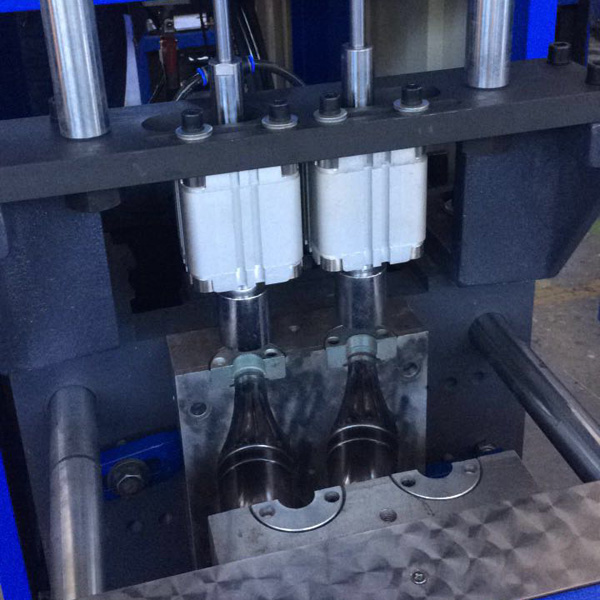

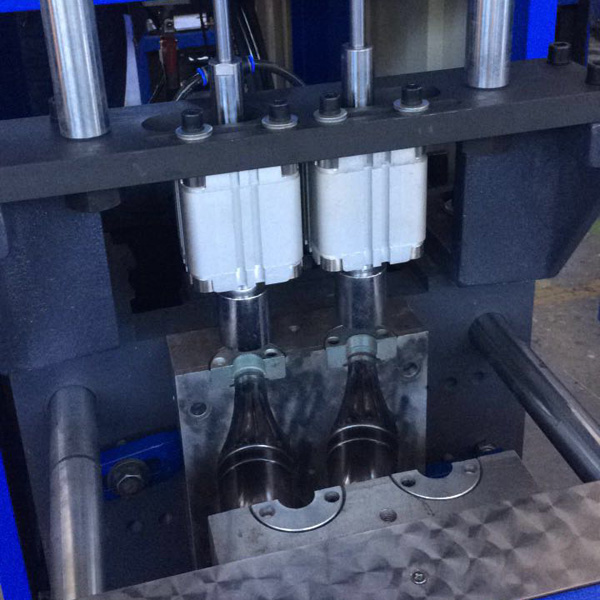

Detailed Photos of Semi-automatic Bottle Blowing Machine

About us

We have more than 20 years knowledge and experience on PET Water/juice/carbonated drinks production line. Our exporting product includes: Injection molding machine, Pet Preform Mould, bottle blowing machine, Water Treatment system, Filling Machine and Packaging machine etc.

Q: What is the warranty if we buy your machines?

A: We offer the high quality machines with 1 year guarantee start from the machine reach to your factory. Also your share the lifelong technical support.

Q: How about the spare parts?

A: We will send one year enough spare parts together with machines for your stock. During the warranty time, if some spare parts broke without human problem, we will send free for you.

Q: How to install my machines when it arrives? What is the cost?

A: We will send our engineer to your factory to install the machines and train your engineers how to operate and maintain the machines. Customer pay for visa, round-trip tickets, room and accommodation, also USD80/day/ person(engineer salary).

Q: How long time for installation?

A: According to the machine you order, usually we will send one or two engineer, it takes about 7to 20days.

Q: When can I get my machine after I paid?

A: Usually the production time is around 25-60 days. The exactly will be decided by which machine u order.

Product Categories : Bottle Blowing Machine > Semi-automatic Bottle Blowing Machine