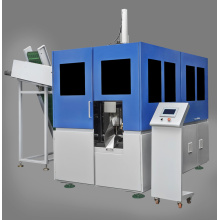

The 2000BPH Water Bottle Making Machine is a high-quality, efficient, and reliable solution for producing water bottles. With a production capacity of 2000 bottles per hour, this machine is perfect for small to medium-sized bottling plants. It features advanced technology and precision engineering, ensuring consistent and top-notch bottle production. The machine is easy to operate, with user-friendly controls and a smooth production process. It is designed to handle various bottle sizes and shapes, making it versatile for different packaging requirements. Built with durability in mind, this machine is made from high-quality materials, ensuring long-lasting performance and minimal maintenance. Invest in the 2000BPH Water Bottle Making Machine and streamline your water bottle production process.

Product Description

WBM-3 is a two-step method full automatic water Bottle Making Machine.This type Automatic Blowing Machine max. capacity is 1.5L, suitable for blowing PET water bottle, juice bottle, carbonated bottle and some other common bottles.

Water Bottle Making Machine Feature

- Blowing 0.5-1.5L PET common bottle.

- Durable PLC micro controlling system controls time can be accurate to 0.01 seconds.

- Special recycling installation for high pressure air reduces the energy consumption

- The far-infrared heater uses a way of conversion self-rotating heating and the rail revolution makes the heating even, quick and reliable.

- Every heating lamp has independent temperature control device, to get the ideal preform heating effect.

- Particular pre-heater design makes preform close while heating. Changing space, shorten heating tunnel and reduce energy consumption according to the bottle size while blowing.

- simple installation and starting

Technical Parameter

| ITEM | UNIT | WBM-3 |

| PRODUCT | Theoretical output | Pcs/hr | 2200 |

| Max. Volume | L | 1.5 |

| Max. Height | MM | 360 |

| Max. Diameter | MM | 105 |

| MOLDING | Number of Cavities | / | 3 |

| Mould Plate Dimension(L×H) | MM | 490×470 |

| Mould Thickness | MM | 240 |

| Mould Opening Stroke | MM | 220 |

| ELECTRICAL | Power |

| 220-380V/50-60HZ |

| Total Power | KW | 18 |

| Heating Power | KW | 15 |

| AIR SYSTEM | Operation Pressure | Mpa | 0.8-1.0 |

| Action Air Consuming | M³/min | ≥1.0 |

| Blowing Pressure | MPA | 2.6-3.0 |

| Blowing Air Consuming | M³/min | ≥1.6 |

| MACHINE | Main Body Dimension(L×W×H) | M | 2.05×1.45×2.5 |

| Main Body Weight | KG | 1500 |

| Preform Autoloader (L×W×H) | M | 1.7×2.1×2.2 |

| Preform Autoloader Weight | KG | 200 |

| Bottle Conveyor(L×W×H) | M | 2.0×0.6×1.1 |

| Bottle Conveyor Weight | KG | 80 |

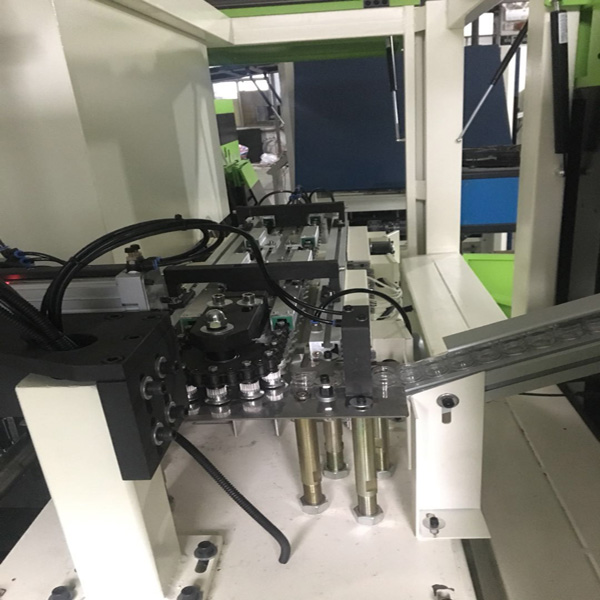

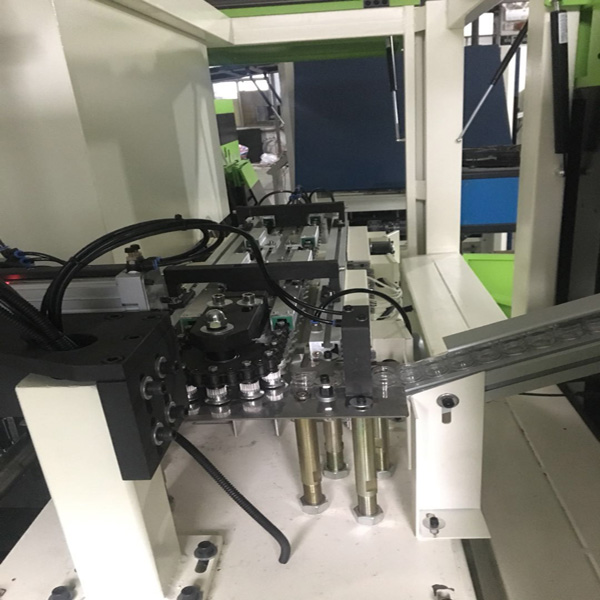

Detailed Photos of WBM-3 Water Bottle Making Machine

About us

We have more than 20 years knowledge and experience on PET Water/juice/carbonated drinks production line. Our exporting product includes: Injection molding machine, Pet Preform Mould, water bottle making machine, Water Treatment system, Filling Machine and Packaging machine etc.

Q: What is the warranty if we buy your machines?

A: We offer the high quality machines with 1 year guarantee start from the machine reach to your factory. Also your share the lifelong technical support.

Q: How about the spare parts?

A: We will send one year enough spare parts together with machines for your stock. During the warranty time, if some spare parts broke without human problem, we will send free for you.

Q: How to install my machines when it arrives? What is the cost?

A: We will send our engineer to your factory to install the machines and train your engineers how to operate and maintain the machines. Customer pay for visa, round-trip tickets, room and accommodation, also USD80/day/ person(engineer salary).

Q: How long time for installation?

A: According to the machine you order, usually we will send one or two engineer, it takes about 7to 20days.

Q: When can I get my machine after I paid?

A: Usually the production time is around 25-60 days. The exactly will be decided by which machine u order.

Product Categories : Bottle Blowing Machine > Automaic Bottle Blowing Machine