Introducing our state-of-the-art PET Plastic Bottle Making Blowing Machine, designed to revolutionize your bottle production process. This high-performance machine boasts advanced technology, ensuring precision and efficiency in every step. Crafted with durable materials, it guarantees long-lasting performance and minimal maintenance. With its user-friendly interface and intuitive controls, our blowing machine allows for easy operation and seamless integration into your existing production line. Its versatile design accommodates various bottle sizes and shapes, offering flexibility to cater to your specific requirements. Experience unmatched productivity, superior quality, and cost-effectiveness with our PET Plastic Bottle Making Blowing Machine. Invest in the future of your business today.

Product Description

PET Plastic Bottle Making Blowing Machine uses the international advanced bottle technology. High pressure compressed gas to blow PET preforms into a type. This machine needs to use a preform suitable for the blown bottle type. The series of fully automatic blow molding machines can be used to independently blow the bottle or to blow the bottle in front of the filling line. It can also be used for blowing the bottle in the blow-drying machine. Standard cavity (bottle volume 0.1-2L) , used in the production of PET bottles of various beverages.

PET Plastic Bottle Making Blowing Machine Feature

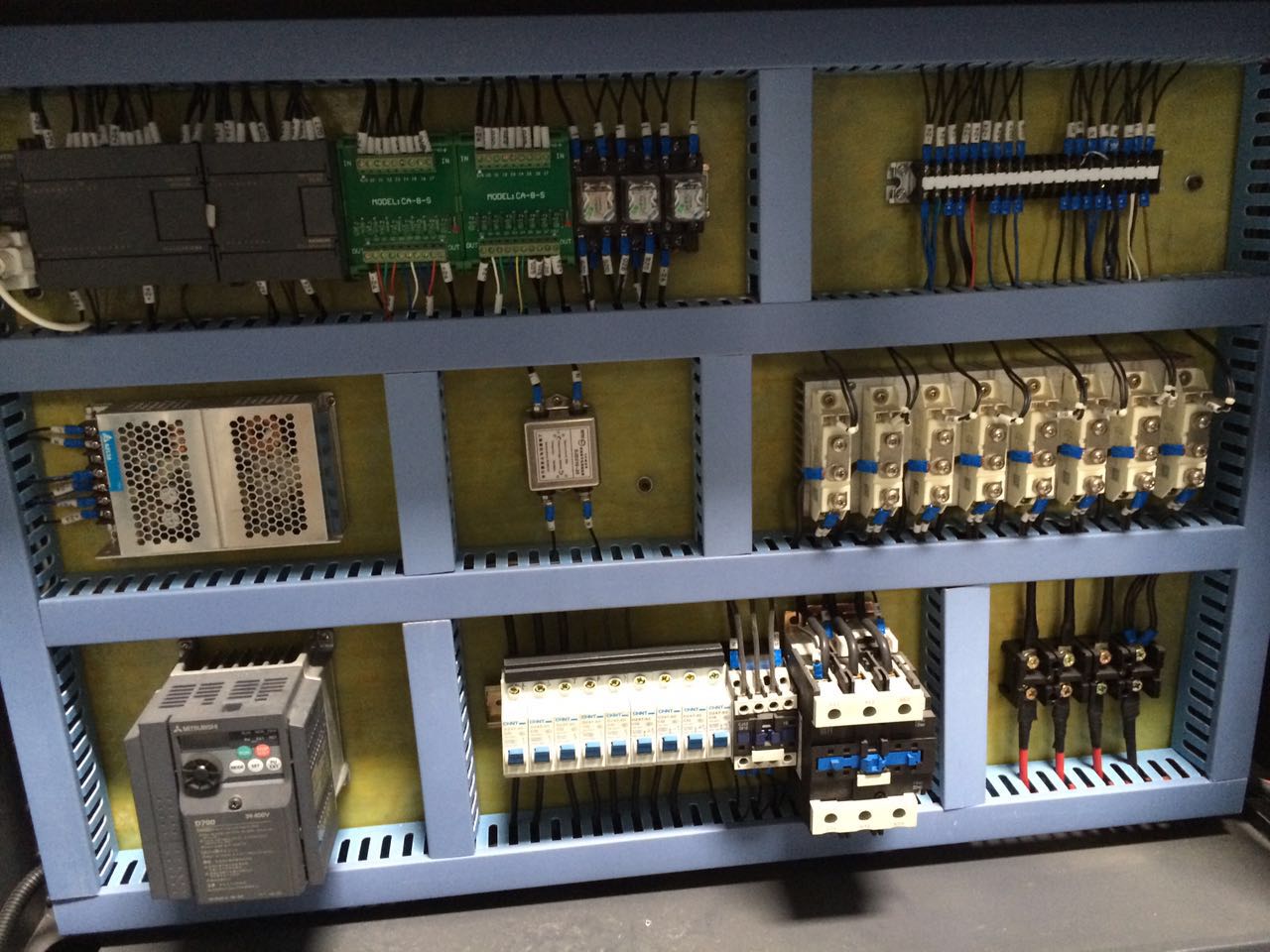

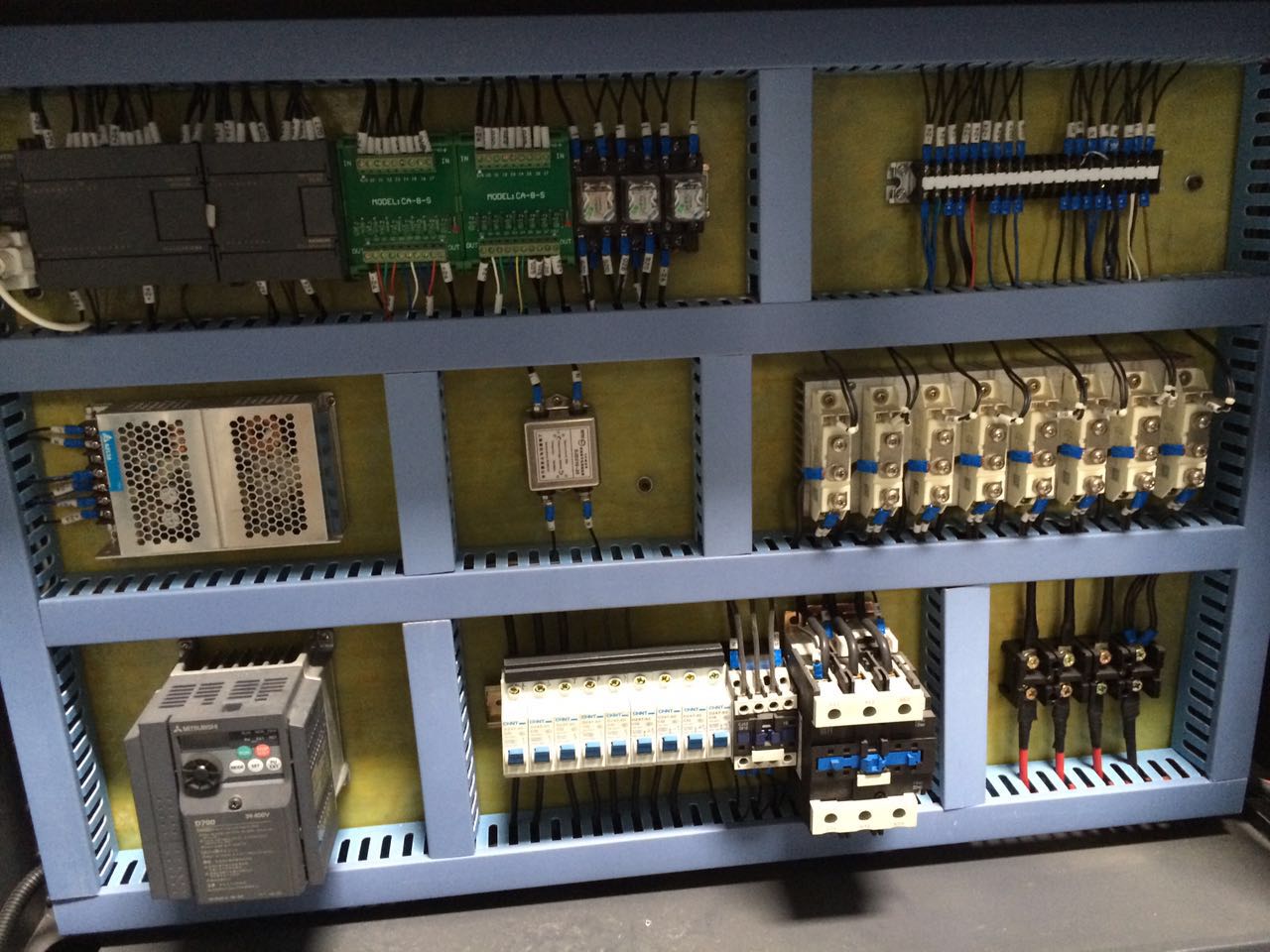

.Adopt human-computer interface to control the whole working procedures, auto-loading, auto blowing, auto dropping. Action cylinders are all assembled with magnetic conduction switches. Connect with PLC to control every step and test every cylinder. Next action will continue after the former step done. If former step is not finished, alarm automatically and do not work. PLC displays problem position.

.Fast Speed, accurate position, smooth action.

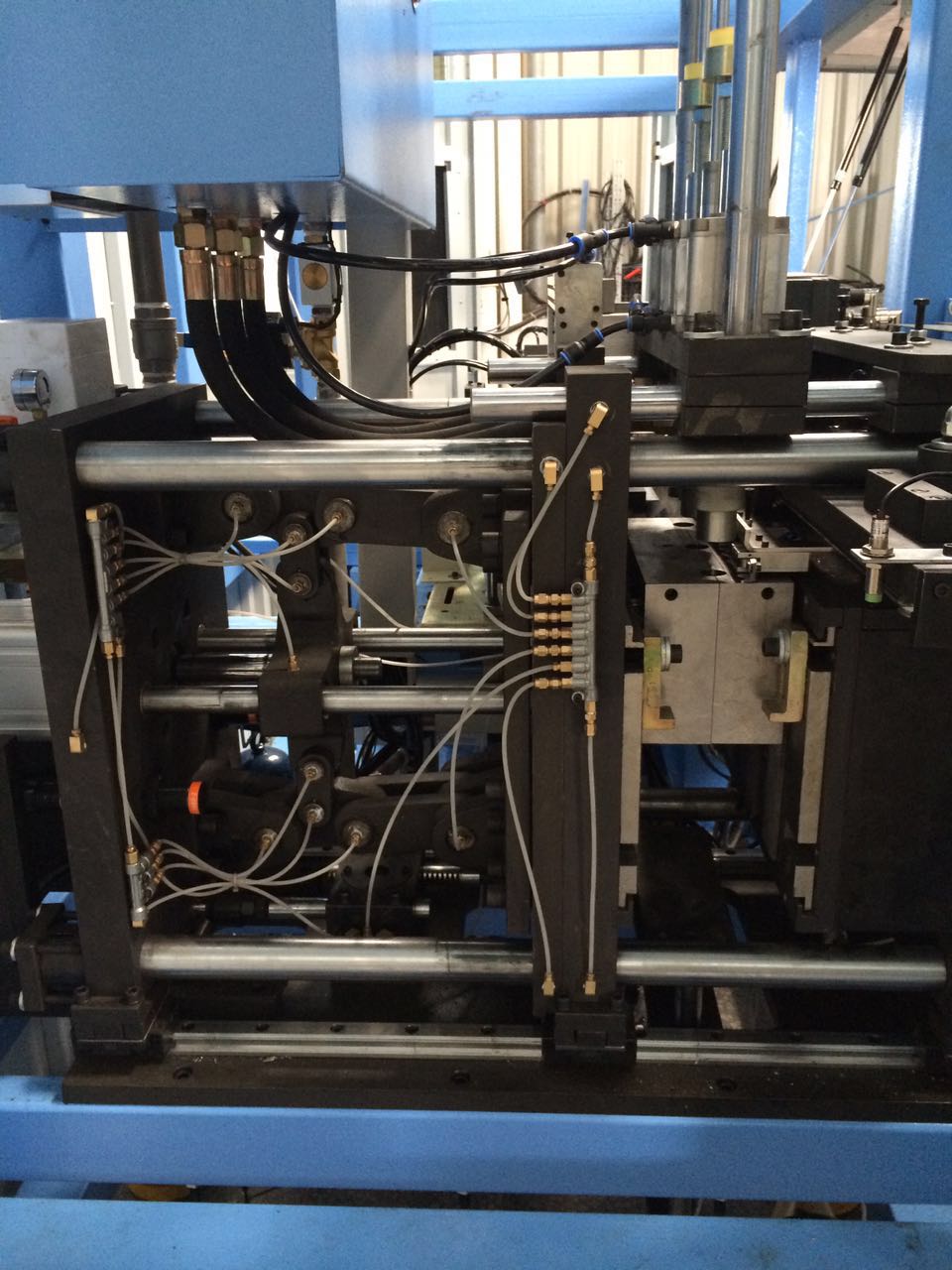

.According to special demand, adopt cross double crank pressed clamping, with strong clamping force. Mould open stroke can be adjustable according to the bottle size to save time.

.Far infrared heater lamps have strong penetrations, preform are heated uniformly while rotating, PLC or electronic pressure adjustor controls each group temperature separately.

.particular pre-heater design makes preform close while heating. Change space, shorten heating tunnel and reduce energy consumption according to the bottle size while blowing.

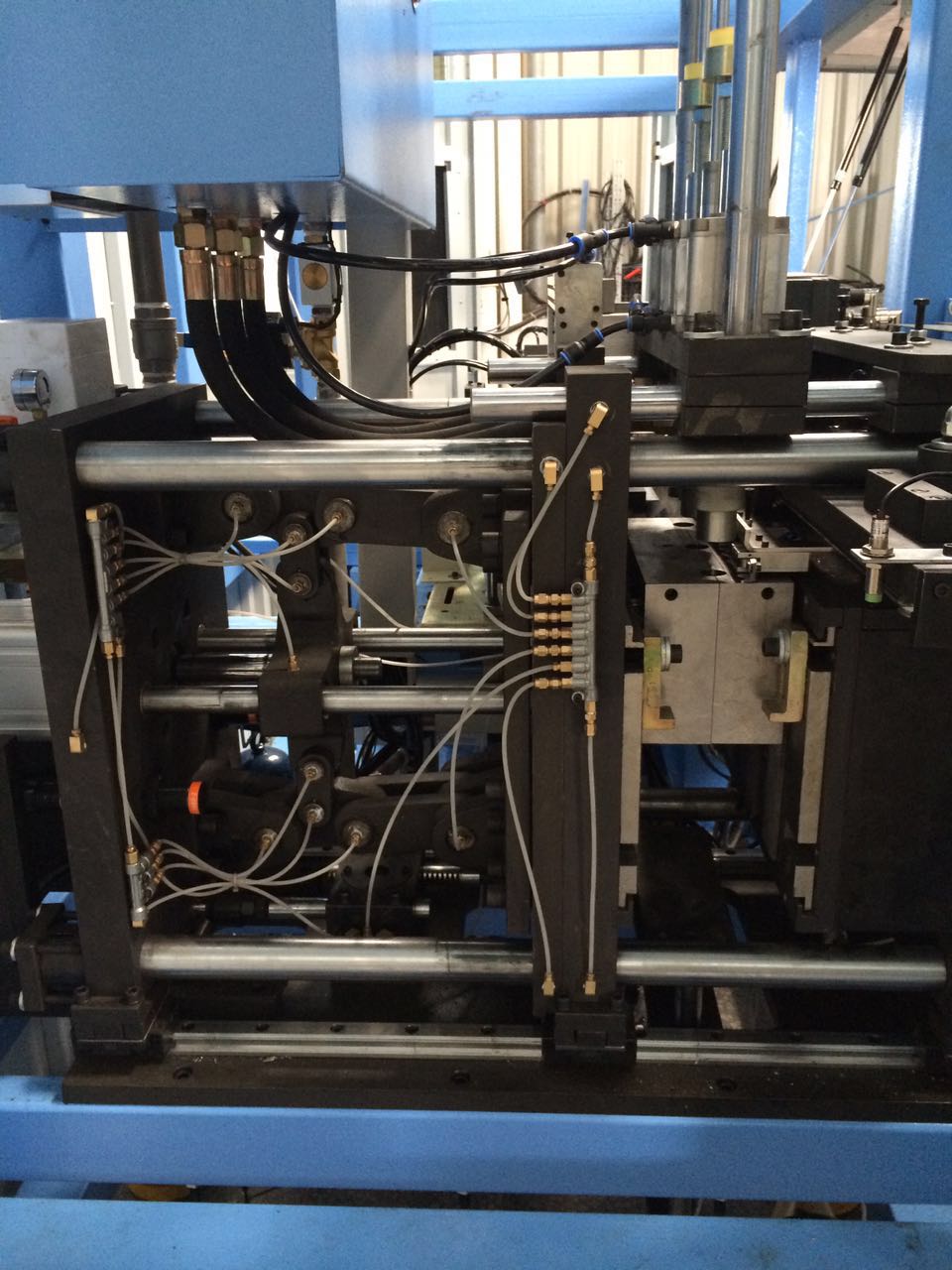

.The air supply system consists of slight blow, high pressure blow, low pressure actions, to supply enough air for different products.

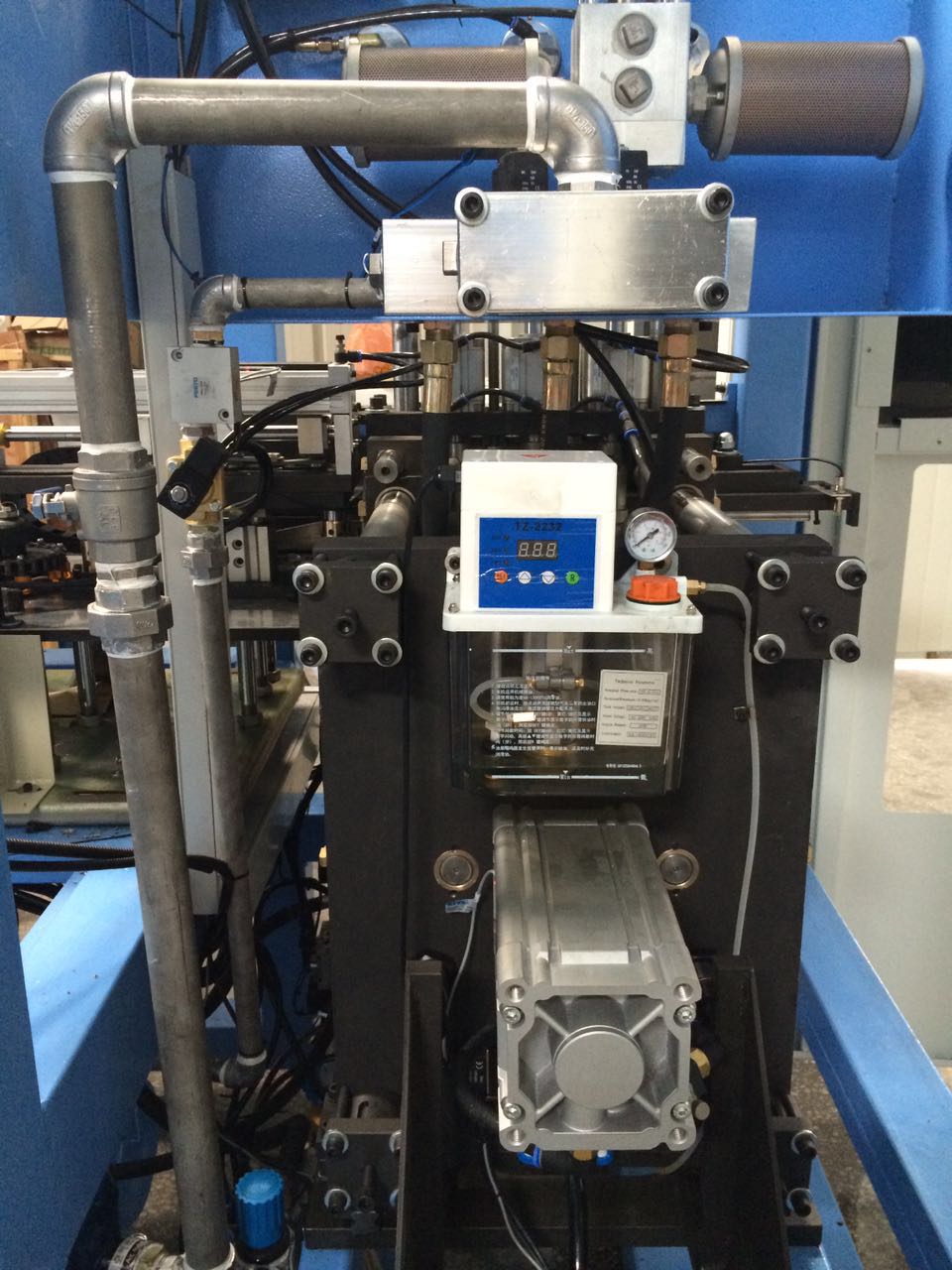

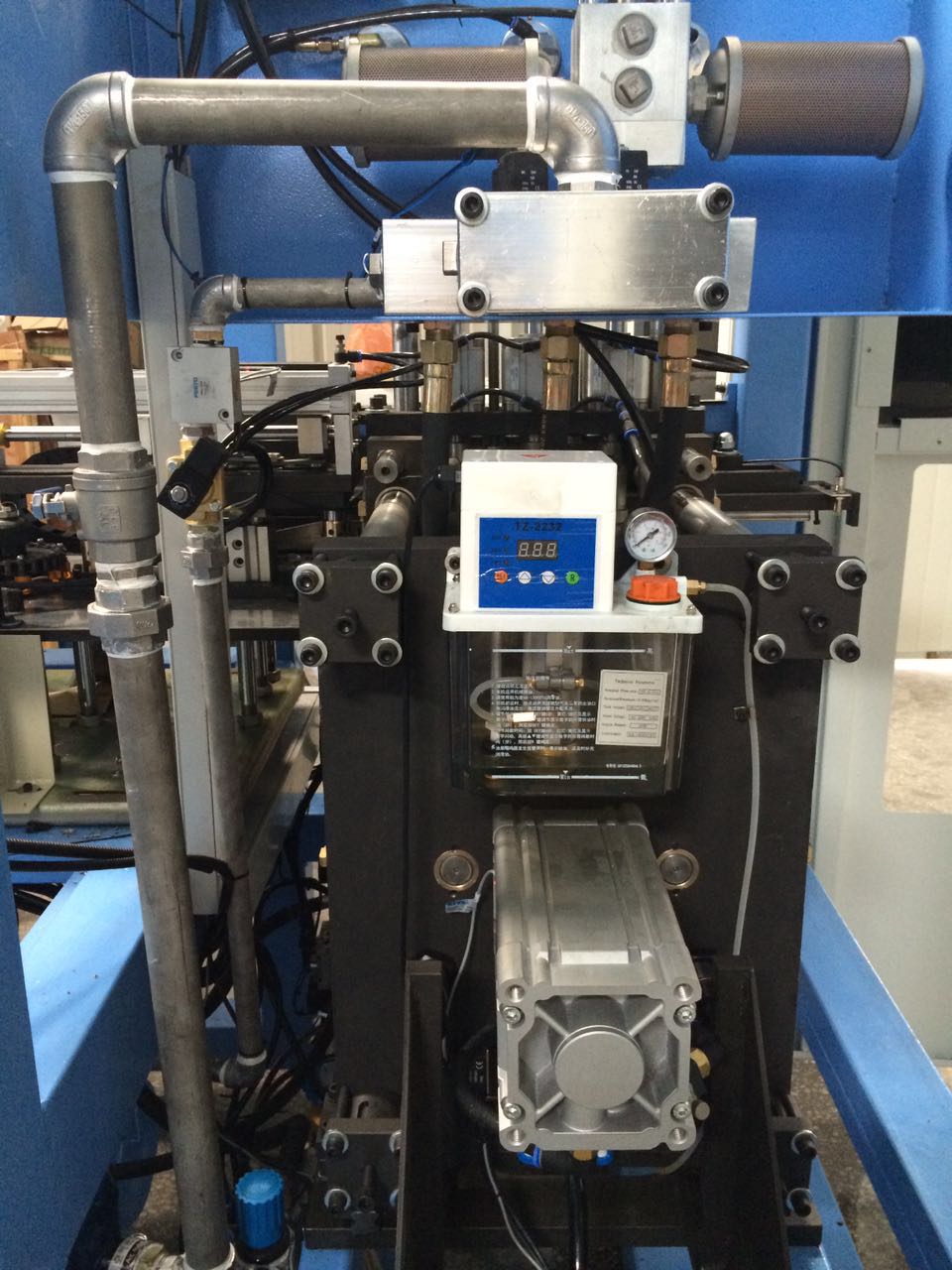

.Connecting rod automatic lubrication oil device protects the machine well.

.Production workmanship process is fully automatic to make best quality and pollution-free. It holds less investment, high efficiency, easy operation, simple repir, safety etc.

Technical Parameter

| ITEM | UNIT | WBB-3 | WBB-4 |

| PRODUCT | Theoretical output | Pcs/hr | 3300 | 4500 |

| Max. Volume | L | 1.5 | 1.5 |

| Max. Height | MM | 360 | 360 |

| Max. Diameter | MM | 105 | 105 |

| MOLDING | Number of Cavities | / | 3 | 4 |

| Mould Plate Dimension(L×H) | MM | 430×360 | 600×360 |

| Mould Thickness | MM | 188 | 188 |

| Mould Opening Stroke | MM | 110 | 110 |

| ELECTRICAL | Power |

| 220-380V/50-60HZ | 220-380V/50-60HZ |

| Total Power | KW | 18 | 25 |

| Heating Power | KW | 15 | 22 |

| AIR SYSTEM | Operation Pressure | Mpa | 0.8-1.0 | 0.8-1.0 |

| Action Air Consuming | M³/min | ≥1.6 | ≥1.6 |

| Blowing Pressure | MPA | 2.6-4.0 | 2.6-4.0 |

| Blowing Air Consuming | M³/min | ≥2.4 | ≥3.2 |

| MACHINE | Main Body Dimension(L×W×H) | M | 2.7×1.45×2.5 | 3.4×1.9×2.5 |

| Main Body Weight | KG | 2000 | 2600 |

| Preform Autoloader (L×W×H) | M | 1.9×1.9×2.2 | 1.9×1.9×2.2 |

| Preform Autoloader Weight | KG | 200 | 20 |

Product Photos

Factory some machine showing

Inside Structure

Automatic Lubrication Device

Heating System

Electronic

About us

We have more than 20 years knowledge and experience on PET Water Production Line. Our exporting product includes: Injection molding machine, Pet Preform Mould, automatic Pet Blowing Machine, Water Treatment system, Filling Machine and Packaging machine etc.

Q: What is the warranty if we buy your machines?

A: We offer the high quality machines with 1 year guarantee start from the machine reach to your factory. Also your share the lifelong technical support.

Q: How about the spare parts?

A: We will send one year enough spare parts together with machines for your stock. During the warranty time, if some spare parts broke without human problem, we will send free for you.

Q: How to install my machines when it arrives? What is the cost?

A: We will send our engineer to your factory to install the machines and train your engineers how to operate and maintain the machines. Customer pay for visa, round-trip tickets, room and accommodation, also USD80/day/ person(engineer salary).

Q: How long time for installation?

A: According to the machine you order, usually we will send one or two engineer, it takes about 7to 20days.

Q: When can I get my machine after I paid?

A: Usually the production time is around 25-60 days. The exactly will be decided by which machine u order.

Product Categories : Bottle Blowing Machine > Automaic Bottle Blowing Machine