Introducing our state-of-the-art Blow Molding Machine for Sale, designed to revolutionize your production line. Engineered with precision and efficiency in mind, this machine boasts a robust construction and cutting-edge technology, ensuring seamless operation and exceptional output. With its user-friendly interface, professionals can easily control and monitor every aspect of the molding process, guaranteeing consistent and high-quality results. Whether you're in the packaging, automotive, or consumer goods industry, this machine is versatile enough to handle a wide range of materials, including HDPE, PVC, and PET. Invest in our Blow Molding Machine for Sale and elevate your manufacturing capabilities to new heights.

Product Description

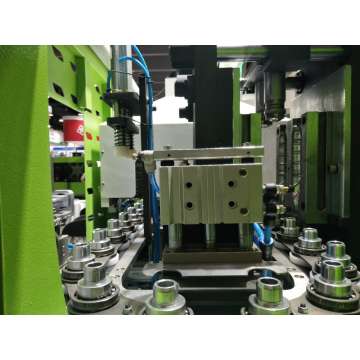

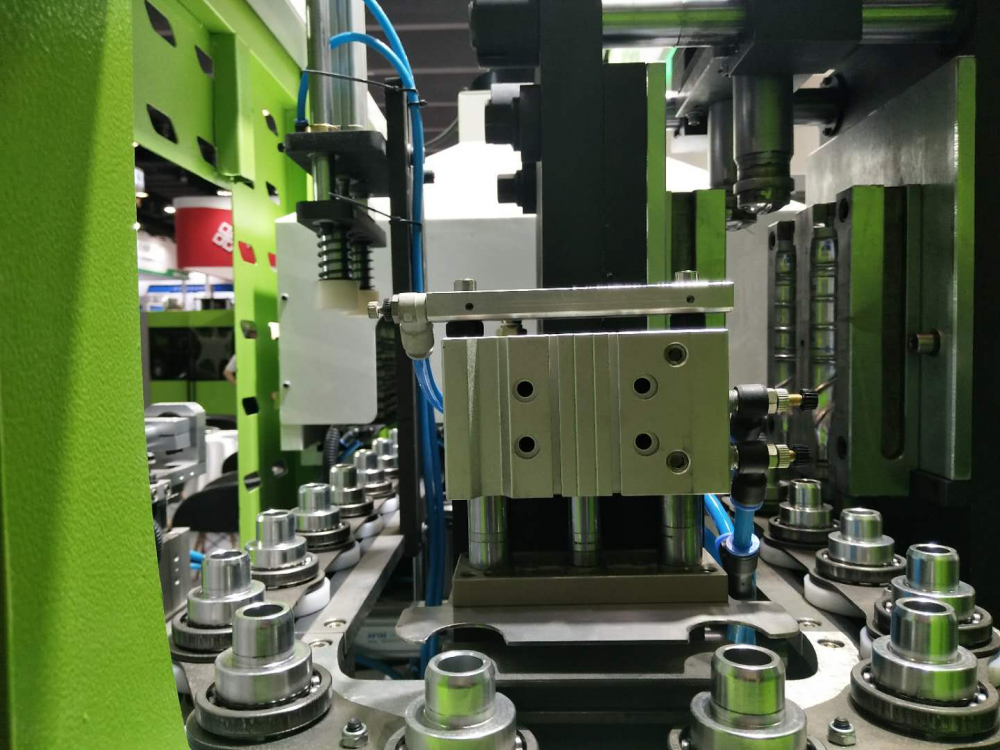

2 Cavity Blow Molding Machine for sale. Plastic Bottle Blow Molding Machine is mainly applied to produce PET mineral water bottles, beverage bottles, edible oil bottles, cosmetic bottles, pesticides bottles and other plastic packing containers.

Full automatic feed preform to machine, automatic blowing without manuel operation which can be connected with filling line directly. 2cavity output can be reached to 2500BPH. Economic machine choice!

- Max. 1.5L Bottle

- Adopt PLC micro controlling system

- Special recycling installation to transfer some high pressure air to low pressure

- The far-infrared heater uses a way of conversion self-rotating heating and the rail revolution makes the heating even, quick and reliable.

- Every heating lamp has independent temperature control device, to get the ideal preform heating effect.

- Particular pre-heater design makes preform close while heating. Changing space, shorten heating tunnel and reduce energy consumption according to the bottle size while blowing.

- simple installation and starting

Technical Parameter

| Model | | UNIT | AL-2 |

| CONTAINER | Max. Capacity | L | 1.5 |

| | Max. Neck Diameter | mm | 38 |

| | Max. Body Diameter | mm | 95 |

| | Max. Bottle Height | mm | 320 |

| | Number of Cavity | PC | 2 |

| | Theoretical Output | B.P.H | 2500 |

| ELECTRICAL | Installed Power | KW | 34 |

| | Max. Heating Power | KW | 32 |

| AIR SYSTEM | Operating Pressure | MPA | 0.7 |

| | Low Pressure Air Consuming | L/Min | 1400 |

| | Blowing Pressure | Bar | 3.5 |

| | High Pressure consuming | L/Min | 2000-3000 |

| WATER CHILLER | Pressure | Mpa | 0.3-0.5 |

| | Temperature Range | ℃ | 10-12 |

| | Flow Rate | L/Min | 60 |

| | Cooling capacity | HP | 5 |

| MACHINE DIMENSION | Size(L*W*H) | M | 2.5*1.4*2.3 |

| | Weight | KG | 1600 |

About us

We have more than 20 years knowledge and experience on PET Water/juice/carbonated drinks production line. Our exporting product includes: Injection molding machine, Pet Preform Mould, water bottle making machine, Water Treatment system, Filling Machine and Packaging machine etc.

Q: What is the warranty if we buy your machines?

A: We offer the high quality machines with 1 year guarantee start from the machine reach to your factory. Also your share the lifelong technical support.

Q: How about the spare parts?

A: We will send one year enough spare parts together with machines for your stock. During the warranty time, if some spare parts broke without human problem, we will send free for you.

Q: How to install my machines when it arrives? What is the cost?

A: We will send our engineer to your factory to install the machines and train your engineers how to operate and maintain the machines. Customer pay for visa, round-trip tickets, room and accommodation, also USD80/day/ person(engineer salary).

Q: How long time for installation?

A: According to the machine you order, usually we will send one or two engineer, it takes about 7to 20days.

Q: When can I get my machine after I paid?

A: Usually the production time is around 25-60 days. The exactly will be decided by which machine u order.

Product Categories : Bottle Blowing Machine > Automaic Bottle Blowing Machine