Introducing the "Blow-o-Matic 3000" - the fully automatic blow moulding machine that will blow your mind (and your bottles)! Say goodbye to manual labor and hello to effortless bottle production. This beast of a machine is so smart, it practically has a PhD in bottle blowing. Whether you need a gazillion soda bottles or a million milk jugs, the Blow-o-Matic 3000 has got you covered. With its sleek design and cutting-edge technology, you'll feel like you're in a sci-fi movie every time you press that start button. Get ready to witness the magic of blowing bottles like a boss - it's a breath of fresh air!

Product Description

Fully Automatic Blow Moulding Machine is suitable for producing PET plastic containers and bottles. It is widely used to produce the carbonated bottle, mineral water bottle, pesticide bottle, oil bottle, cosmetics, wide-mouth bottle etc. Adopt double crank to adjust mould, double servo motor control system, stable and fast. Also infrared oven to heat the preform, the preform rotated and heated equally.

Automatic Blow Moulding Machine Feature

- Horizontal rotation transfer system make the construction and maintance more easy, reduce the cost of spare part changing.

- Compact preform heating distance design for efficient heating and reduce energy consumption.

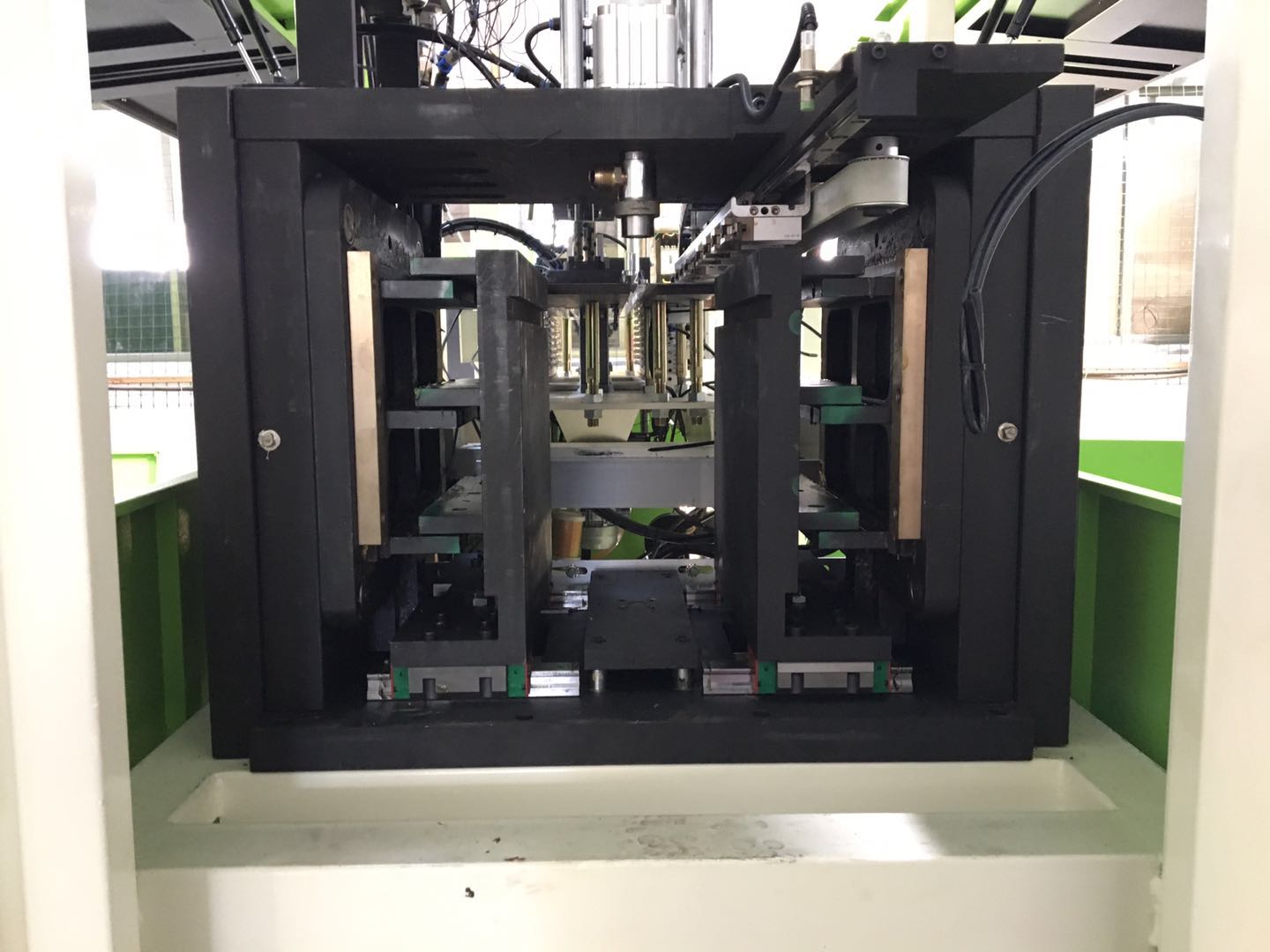

- Mould closing adopts CAM linkage, no chain plate pins shaft make it small volume and long life.

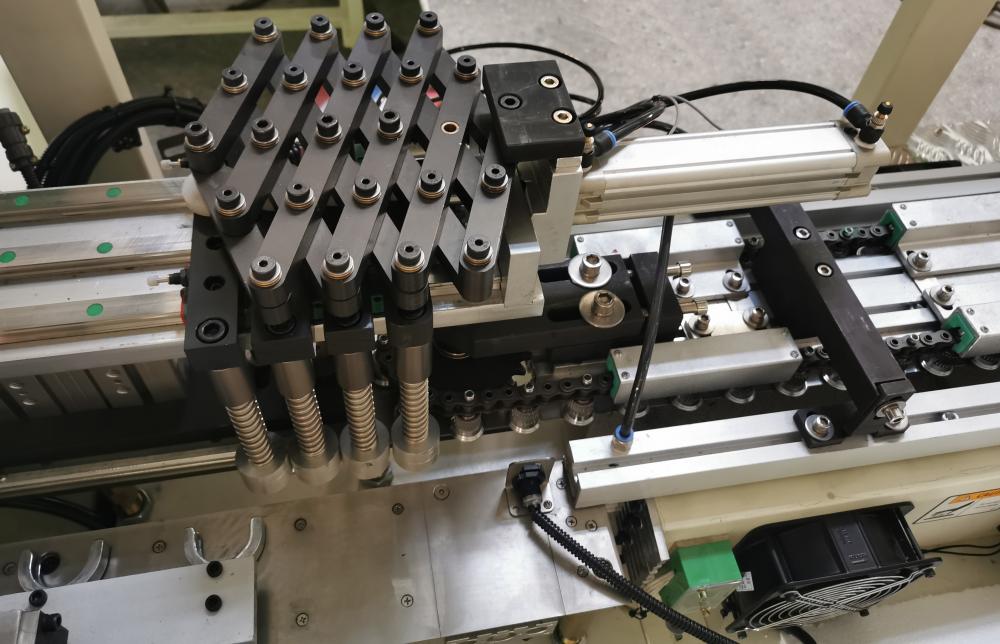

- Using hard claw to catch the preform and bottle, resistance to wear with long life.

- Servo motor drive system with synchronized base blow mould for fast response operation, precision blowing valve for high output.

- Stainless steel pipe make the air more clean without pollution

- slip for bottle mould make the installation more easy.

- Touch-panel control system for simple operation with 9 inch LCD screen.

Technical Parameter

| ITEM | UNIT | WBB-4HS |

| PRODUCT | Theoretical output | Pcs/hr | 6500 |

| Max. Volume | L | 1.5 |

| Max. Height | MM | 360 |

| Max. Diameter | MM | 105 |

| MOLDING | Number of Cavities | / | 4 |

| Mould Plate Dimension(L×H) | MM | 840×360 |

| Mould Thickness | MM | 198 |

| Mould Opening Stroke | MM | 110 |

| ELECTRICAL | Power |

| 220-380V/50-60HZ |

| Total Power | KW | 22 |

| Heating Power | KW | 21 |

| AIR SYSTEM | Operation Pressure | Mpa | 0.8-1.0 |

| Action Air Consuming | M³/min | ≥1.6 |

| Blowing Pressure | MPA | 2.6-4.0 |

| Blowing Air Consuming | M³/min | ≥4.8 |

| MACHINE | Main Body Dimension(L×W×H) | M | 3.74×1.2×2.3 |

| Main Body Weight | KG | 2200 |

| Preform Autoloader (L×W×H) | M | 1.9×1.9×2.2 |

| Preform Autoloader Weight | KG | 200 |

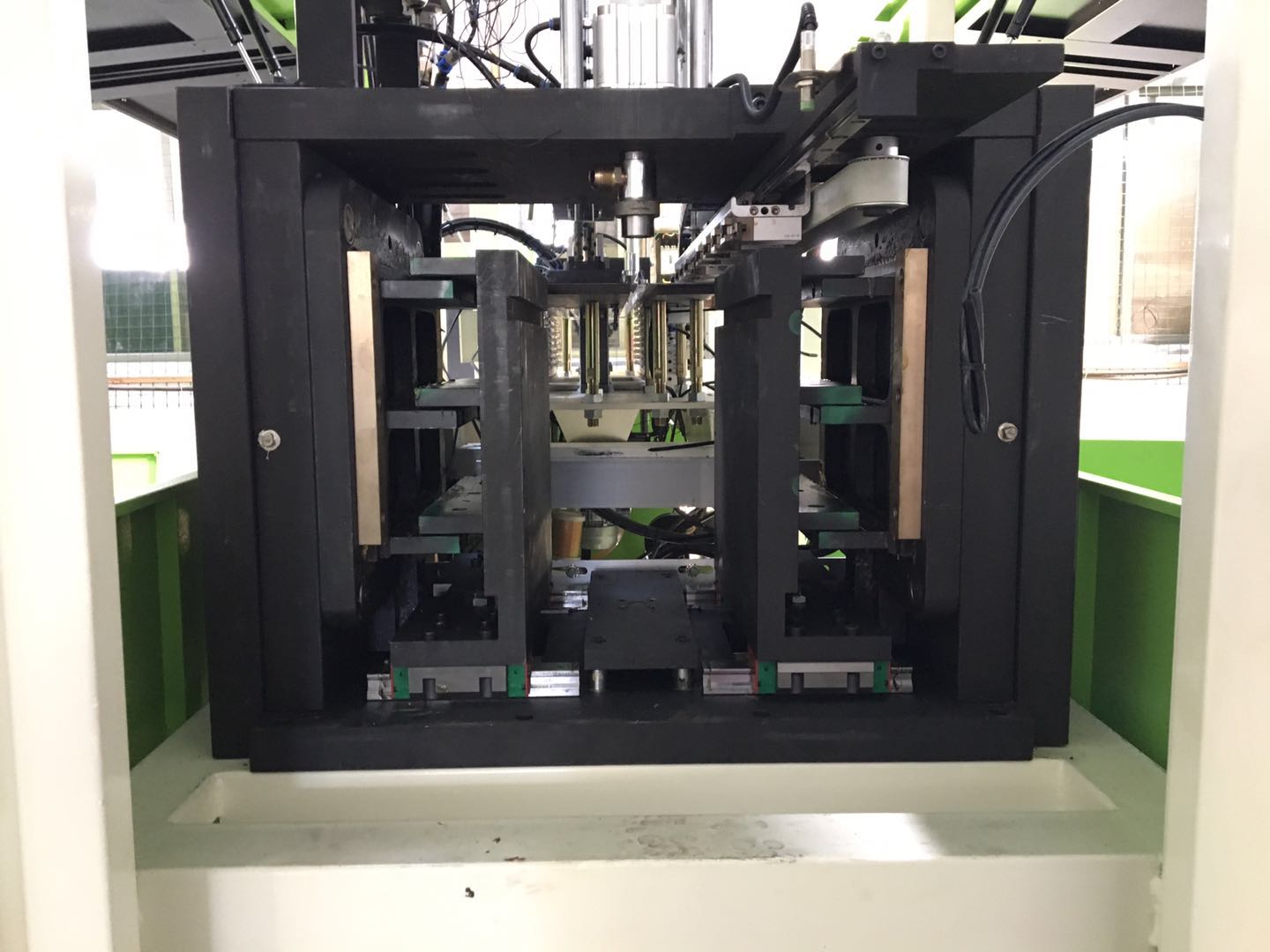

Automatic Blow Molding Machine Product photos

About us

We have more than 20 years knowledge and experience on PET Water/juice/carbonated drinks production line. Our exporting product includes: Injection molding machine, Pet Preform Mould, automatic Pet Blow Molding machine, Water Treatment system, Filling Machine and Packaging machine etc.

Q: What is the warranty if we buy your machines?

A: We offer the high quality machines with 1 year guarantee start from the machine reach to your factory. Also your share the lifelong technical support.

Q: How about the spare parts?

A: We will send one year enough spare parts together with machines for your stock. During the warranty time, if some spare parts broke without human problem, we will send free for you.

Q: How to install my machines when it arrives? What is the cost?

A: We will send our engineer to your factory to install the machines and train your engineers how to operate and maintain the machines. Customer pay for visa, round-trip tickets, room and accommodation, also USD80/day/ person(engineer salary).

Q: How long time for installation?

A: According to the machine you order, usually we will send one or two engineer, it takes about 7to 20days.

Q: When can I get my machine after I paid?

A: Usually the production time is around 25-60 days. The exactly will be decided by which machine u order.

Product Categories : Bottle Blowing Machine > Automaic Bottle Blowing Machine